Estrutura da bomba de óleo automotiva

Função: aumente a pressão do óleo para garantir que o óleo circule continuamente no sistema de lubrificação e forneça uma quantidade suficiente de óleo para a peça de lubrificação a uma pressão alta o suficiente em qualquer rotação do motor.

Atualmente, o sistema de lubrificação do motor é amplamente utilizado na bomba de óleo tipo engrenagem e bomba de óleo tipo rotor dois tipos.

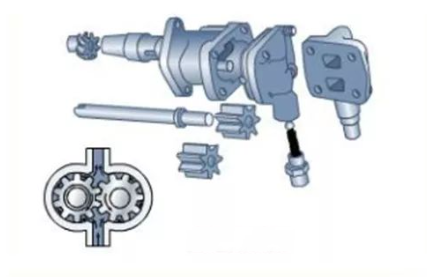

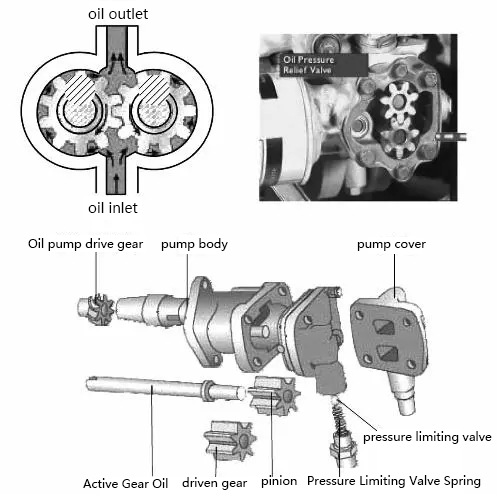

- Bomba de óleo tipo engrenagem

As bombas de óleo de engrenagem são divididas em dois tipos: bombas de óleo de engrenagem externa e bombas de óleo de engrenagem internas.

(1) Bomba de óleo de engrenagem externa. A bomba de óleo de engrenagem externa é caracterizada por estrutura simples, processamento conveniente, operação confiável e longa vida útil. É composto principalmente de um eixo de acionamento, uma engrenagem motriz, um eixo acionado, uma engrenagem acionada e uma carcaça. Duas engrenagens com o mesmo número de dentes engrenam entre si e são instaladas na carcaça. As folgas radiais e finais entre a engrenagem e a carcaça são pequenas. O eixo de acionamento é chaveado na engrenagem motriz e a engrenagem acionada é vagamente revestida no eixo acionado.

Ao trabalhar, a engrenagem motriz aciona a engrenagem acionada para girar ao contrário. Quando as duas engrenagens giram, o óleo preenchido entre as ranhuras dos dentes das engrenagens é transportado da câmara de entrada de óleo para a câmara de saída de óleo ao longo da parede da carcaça da bomba de óleo. Na lateral da câmara de entrada de óleo, um vácuo é gerado devido ao desengate da engrenagem e ao óleo sendo continuamente trazido para fora, de modo que o óleo no cárter de óleo entre na câmara de entrada de óleo através do filtro sob a ação da pressão atmosférica, enquanto no lado da câmara de saída de óleo devido a As engrenagens entram em malha e o óleo é continuamente trazido para produzir uma ação de compressão, e o óleo é bombeado para fora com uma certa pressão.As bombas de óleo de malha externa são caracterizadas por uma estrutura simples, fácil processamento, operação confiável e longa vida útil.

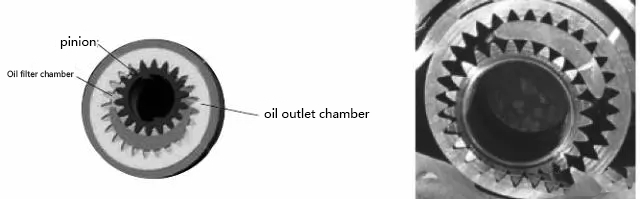

(2) Bomba de óleo de engrenagem interna. Estrutura da bomba de óleo de malha interna. A engrenagem motriz aciona a coroa acionada para girar, e o volume da câmara no lado onde a engrenagem externa e a engrenagem interna se desengata torna-se maior. Sob a ação da pressão negativa, o óleo entra na câmara; continua a girar e a câmara de armazenamento de óleo perto da porta de descarga de óleo O volume diminuirá gradualmente até que esteja totalmente engatado e o óleo seja expelido.

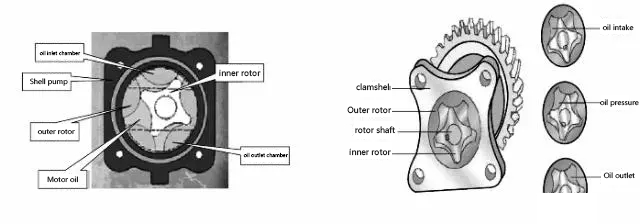

2. Bomba de óleo do rotor

A bomba de óleo tipo rotor é composta por uma carcaça, um rotor interno, um rotor externo e uma tampa da bomba, etc. O rotor interno é fixado no eixo do rotor com chaves ou pinos e é acionado direta ou indiretamente pela engrenagem do virabrequim. A distância excêntrica entre os centros do rotor interno e do rotor externo é e, e o rotor interno aciona o rotor externo para girar juntos na mesma direção. O rotor interno tem 4 dentes convexos e o rotor externo tem 5 dentes côncavos, de modo que os rotores interno e externo giram na mesma direção, mas não de forma síncrona.

O perfil do dente do rotor é projetado para que, quando o rotor gira em qualquer ângulo, o perfil do dente de cada dente dos rotores interno e externo possa sempre formar um ponto de contato entre si. Desta forma, quatro câmaras de trabalho são formadas entre os rotores interno e externo, e os volumes dessas quatro câmaras de trabalho mudam constantemente à medida que o rotor gira. Na cavidade de um lado da passagem de entrada de óleo, devido ao desengate do rotor, o volume aumenta gradualmente, um vácuo é gerado, o óleo é sugado, o rotor continua a girar e o óleo é levado para o lado da passagem de saída de óleo. Nesse momento, o rotor apenas entra na malha, de modo que o volume dessa cavidade diminui, a pressão do óleo aumenta e o óleo é espremido entre os dentes e enviado pela passagem do óleo. Desta forma, com a rotação contínua do rotor, o óleo é continuamente sugado e pressionado para fora.

As características da bomba de óleo tipo rotor são estrutura compacta, peso leve, tamanho pequeno, grande volume de óleo da bomba, boa uniformidade de fornecimento de óleo e baixo custo.